Loading...

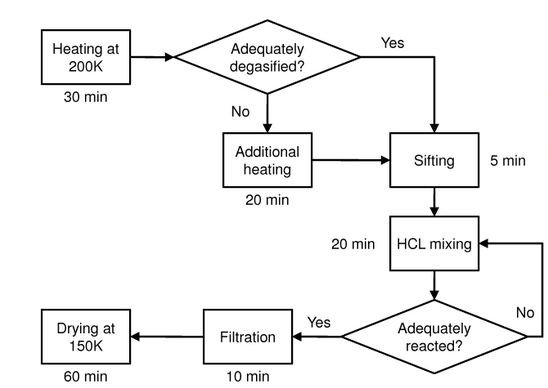

In the flowchart, each rectangular box represents a distinct stage in the production of a 50-kilogram batch of a specialty chemical. Decision points, which are not distinct stages, are represented by diamond shapes. The time required for each stage is indicated in minutes (min). There is no waiting time between stages. Three quarters of all batches do not require additional heating, while half of all batches require a second mixing with hydrochloric acid (HCL); none require a third.

From each drop-down menu, select the option that creates the most accurate statement based on the information provided.

| Text Component | Literal Content | Interpretation |

|---|---|---|

| Process Description | production of a 50-kilogram batch of a specialty chemical | Batch size and product |

| Stage Representation | each rectangular box represents a distinct stage | Rectangles = production steps |

| Decision Representation | diamond shapes = decision points, not distinct stages | Diamonds = quality checks |

| Time Measurement | time for each stage in minutes | All stage times in minutes |

| Flow Between Stages | no waiting time between stages | Stages are contiguous |

| Additional Heating Requirement | Three quarters of all batches do not require additional heating | 25% require additional heating |

| Second HCL Mixing Requirement | Half of all batches require a second mixing with hydrochloric acid (HCL); none require a third | 50% require a second HCL mixing, never a third |

| Chart Component | Shown In Chart | What It Means |

|---|---|---|

| Rectangular Stages | Heating (30min), Additional Heating (20min), Sifting (5min), HCL Mixing (20min), Filtration (10min), Drying (60min) | Up to 6 process stages (but not all used per batch) |

| Diamonds (Decisions) | Adequately degasified? ; Adequately reacted? | Determine extra processing (heating or extra mixing) |

| Conditional Branches | Arrows based on Yes/No at diamonds | Failing a check adds that extra step |

| Minimum Steps | Heating → Sifting → HCL Mixing → Filtration → Drying | Base process: 125 minutes |

| Optional Steps | Additional Heating and/or second HCL Mixing | Add 20 mins (heating) and/or 20 mins (mixing) as needed |

There are four possible process paths: (1) base process with no optional steps (125 min, 37.5%), (2) additional heating only (145 min, 12.5%), (3) second HCL mixing only (145 min, 37.5%), and (4) both additional steps (165 min, 12.5%). The average total process time is 140 minutes. On average, a batch passes through 5.75 distinct process stages, reflecting the probabilistic addition of heating and mixing steps.

The average time in minutes that a batch of ingredients to make it all the way through the process shown is:

The average number of stages that a batch undergoes is:

Both questions relied on calculating a weighted average using the probabilities of taking each possible process path. The solution to the first blank focused on average process time, while the second blank focused on average number of stages completed. Both required understanding the process flow, decision points, and how different pathways affect the overall average. The answers are 140 minutes and 5.75 stages, respectively.

The two blanks are independent: one asks for average time and the other for the average number of stages. Both use the same probabilities, but solving one does not directly yield the solution for the other.